PE Pressure Pipe Production Line High Ring Stiffness Extrusion Line

PPR Pipe Production Line

HDPE pressure Pipe Extrusion Line is a pipe extrusion line

developed by HSD company through assimilate and master technology

introduced from abroad. It is applicable for extrusion of PE, PP,

PB, PERT, ABS etc. This PE pipe production line can instead

extrusion line imported from abroad.

This pipe extrusion line mainly includes single screw extruder,

molds, vacuum calibrating water tank, spray water cooling tank,

haul-off machine, cutting machine and bracket.

Plastic Pipes produced by this line have excellent stiffness,

flexibility, high mechanical strength, resistance of environmental

stress cracks, resistance to creep deformation, heat-linkage and so

on. It has become the first choice for the city gas pipe, water

supply pipe, foundation pipe, landfill collection pipe, watermain,

geothermal heating etc.

Application

HDPE pipe extruding line composed of single screw extruder and

corresponding auxiliaries, can produce all kinds of small diameter

HDPE plastic pipes continuously. It also can be used to produce PS,

PP, HDPE plastic pipes after replacing the screw. HDPE plastic pipe

is widely used for liquid conveying in agricultural, chemical

industry, construction industry, etc.

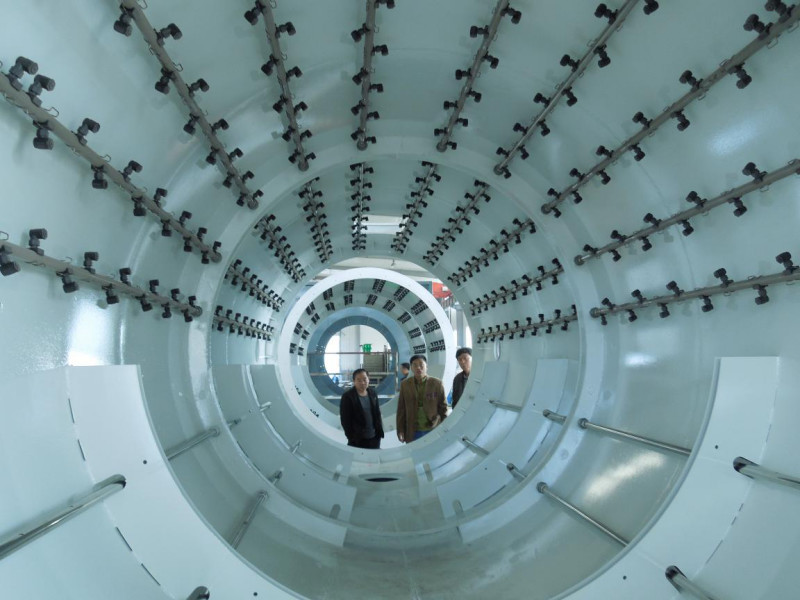

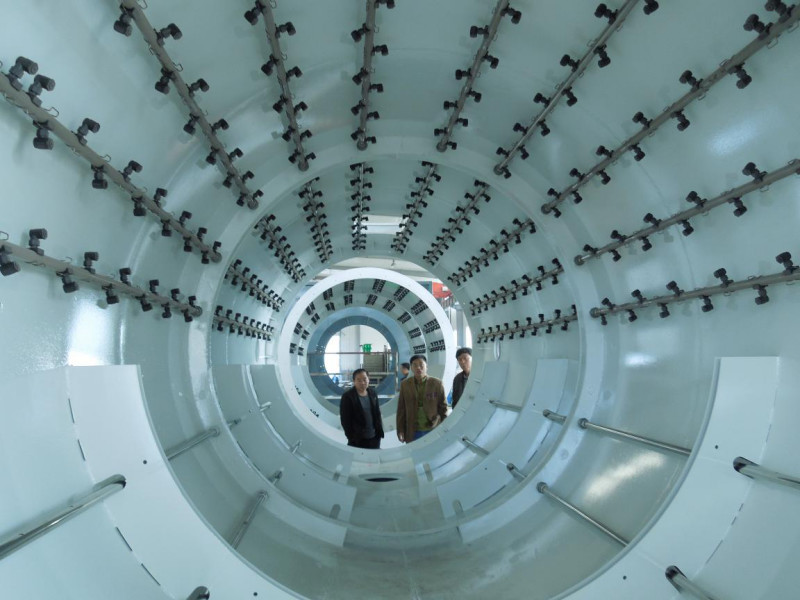

Structure

HDPE pipe extruding line is mainly composed of single screw

extruder, die-head, vacuum forming tank, spray cooling tank,

haul-off device, cutting device, and pneumatic discharging frame.

Single Screw Extruder

Single screw extruder is composed of AC motor, hard toothed surface

reduction gear, extruding system, heating and cooling system, and

electrical controlling part. AC motor transfer the power to

reduction gearbox via V-belt wheel and make screw rotate at certain

speed to adapt to extruding all kinds of plastics.

Die-Head

Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body,

cover, die-head body, bolts, and heating rings. The inside surface

touching with plastic materials is polished and chrome plated to

ensure plastic materials flow smoothly and to ensure no rusting.

The uniformity of pipe wall thickness can be adjusted by bolts. The

copper calibrating sleeve fixed in die-head is mainly used to cool

down the fresh pipe and to calibrate the pipe outer diameter.

II. Machine Advantages

---High-efficiency extruder gives larger output, stable

performance.

For example

SJ90/33---600-700kg/h

SJ120/33---800-900kg/h

SJ150/33---1000-1200kg/h

---Compared with inflating method (internal pressure method)

1. For 24 hours working, it reduces 2-3 workers for each shift.

2. There is much waste pipe and material, no need workers to crush

waste material.

3. High-effeciency. Take Dimater 960mm as an example, Output is

approximately 60 pcs of 11.6meters pipe, it is much higher output

than that of inflating method.

4. Pipe wall is average and smooth, to reduce waste of raw

material, and pipe thickness is adjustable.

5. No need trim edge, once forming.

III. Main machine- High-effeciency single screw extruder

---Single screw is with barreir & mixing head; Barrel is new model

with slotting (channel), Both make security of good jellification,

large output and stable performance.

IV. Controlling system

The complete line could be controlled by PLC, with good

human-machine interface, all technical parameters could be set and

indicated by touching screen. Controlling system is designed

according to the customer; S requirement, to be with PLC, or

without.

Electrical system

---ABB frequency converter or EUROTHERM speed controller

---Japan RKC temperature controller

--- SIEMENS AC contactors

Service

Seller provide the technical service with free, and training the

workers of buyers.

Installation and testing

The seller can send 2 technicians to the buyer’s company for

installation and testing the lines. The round trip ticket,

accommodation, transportation, medicine treatment and insurance

caused by the seller’s expert in buyer’s country and 150 US dollars

per person per day will be covered by the buyer.