Vacuum Calibrating PU Pre-Insulated HDPE Casing Shell Jacket Pipe

Extrusion Line

Product description:

Vacuum Calibrating Method Pre-Insulated Pipe extrusion line is

designed by absorbing the tube extrusion developed technology from

Germany and improved by Qingdao Huashida Machinery Co., Ltd.The

line is an integration design composed by extruder, vacuum

calibrating, cooling, pulling, cutting, stacker. Great performance

in automatic operation, extrusion capacity, steady and service life

etc. Especially compared with the line use internal pressure

method, vacuum calibrating method is much better than it for

stiffness, pressure resistance and surface smooth.

Vacuum calibrating method pre-insulated pipe outside casing

extrusion line is the most advanced and popular machinery in the

world.In the practice of domestic construction becomes increasingly

used energy-saving technology trenchless laying of pipelines, using

pipes and fittings with industrial thermal insulation of rigid

polyurethane foam (PUF insulation) in protective shell.

Pipelines PUF insulation intended for installation of heating

networks with a working pressure of 1.6 MPa and a water temperature

to 403 ° K (130 ° C) with a valid short-term increase in

temperature to 423 ° K (150 ° C).

| Pipe size range | Extrusion |

Speed per h |

Output |

Size of line |

| Model | KW |

| SKRG-800 | 200-800 | SJ65X30

SJ45X30 | 180KW | 6-12m/h | 220kg/h | 23X12X4M |

| SKRG-1200 | 300-1200 | SJ90X30

SJ65X30 | 230KW | 4-12m/h | 300-420kg/h | 26X16X5M |

| SKRG-2000 | 1000-2000 | SJ100X33

SJ75X30 | 400KW | 2-5m/h | 600kg/h | 32X16X6M |

| SKRG-3000 | 2000-3000 | SJ120X33

SJ90X30 | 680KW | 0.5-3m/h | 680kg/h | 42X18X7M |

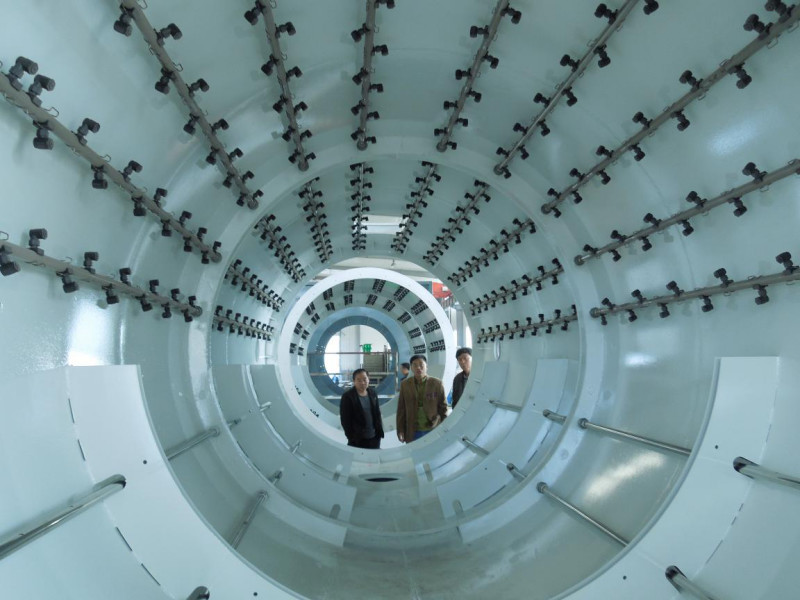

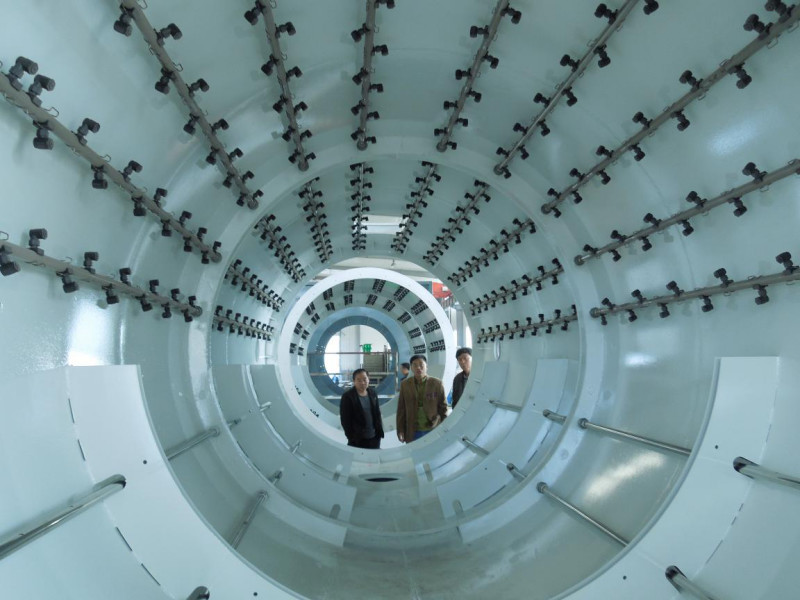

Die-Head

Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body,

cover, die-head body, bolts, and heating rings. The inside surface

touching with plastic materials is polished and chrome plated to

ensure plastic materials flow smoothly and to ensure no rusting.

The uniformity of pipe wall thickness can be adjusted by bolts. The

copper calibrating sleeve fixed in die-head is mainly used to cool

down the fresh pipe and to calibrate the pipe outer diameter.

Machine Advantages

---High-efficiency extruder gives larger output, stable

performance.

For example

SJ90/33---600-700kg/h

SJ120/33---800-900kg/h

SJ150/33---1000-1200kg/h

---Compared with inflating method (internal pressure method)

1. For 24 hours working, it reduces 2-3 workers for each shift.

2. There is much waste pipe and material, no need workers to crush

waste material.

3. High-effeciency. Take Dimater 960mm as an example, Output is

approximately 60 pcs of 11.6meters pipe, it is much higher output

than that of inflating method.

4. Pipe wall is average and smooth, to reduce waste of raw

material, and pipe thickness is adjustable.

5. No need trim edge, once forming.

Main machine- High-effeciency single screw extruder

---Single screw is with barreir & mixing head; Barrel is new model

with slotting (channel), Both make security of good jellification,

large output and stable performance.

Controlling system

The complete line could be controlled by PLC, with good

human-machine interface, all technical parameters could be set and

indicated by touching screen. Controlling system is designed

according to the customer; S requirement, to be with PLC, or

without.

Electrical system

---ABB frequency converter or EUROTHERM speed controller

---Japan RKC temperature controller

--- SIEMENS AC contactors