Product Description:

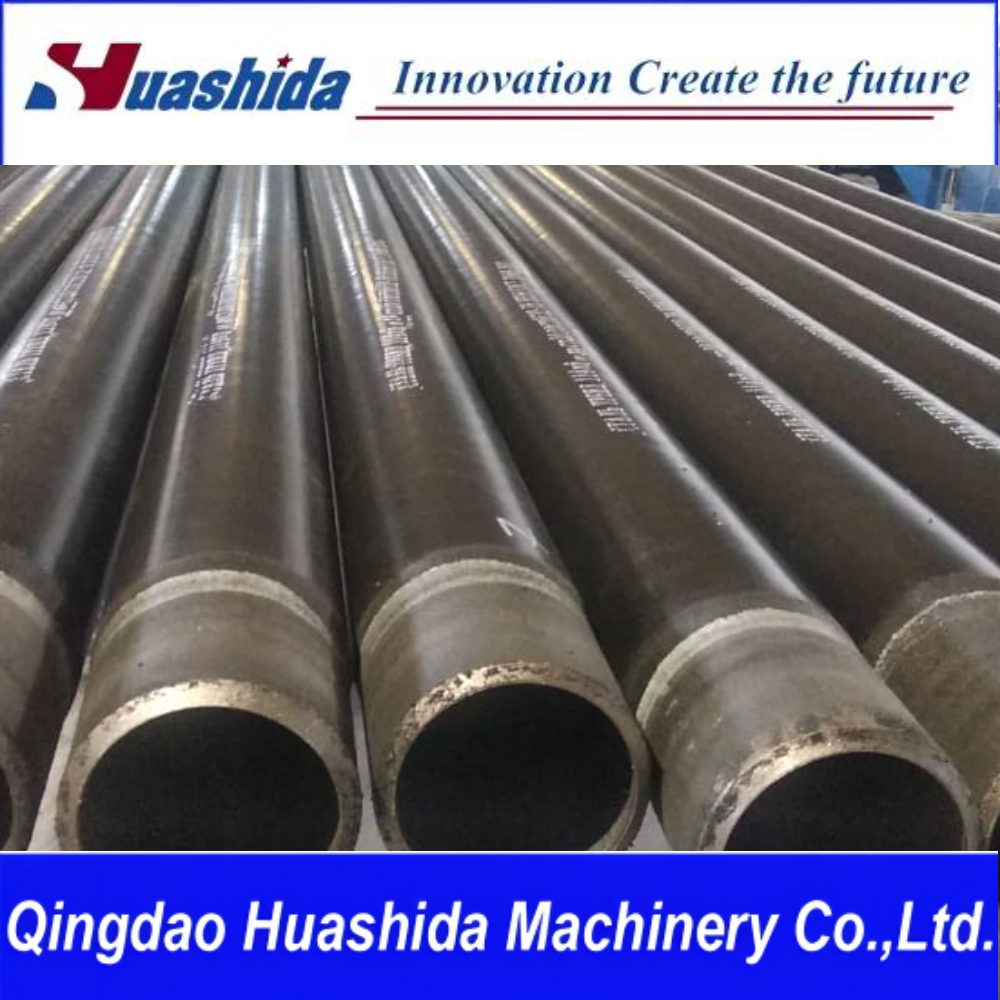

3LPE Steel Pipe Coating Production Line

Product Overview:

The 3LPE (Three-Layer Polyethylene) Steel Pipe Coating Production Line by Qingdao Huashida Machinery Co., Ltd. is engineered for high-performance anti-corrosion coating of steel

pipes. This line supports pipe diameters ranging from 159mm to

1400mm, with an extrusion capacity up to 350 kg/h, customizable to

specific production requirements.

This advanced production line is the result of years of dedicated

development and innovation, fulfilling the increasing market demand

for durable, efficient, and high-performance anti-corrosion

solutions.

3-Layer PE Coating System Composition:

- Fusion-Bonded Epoxy (FBE) Primer Layer

- Polymer Adhesive Middle Layer

- Polyethylene (PE) Top Layer

This 3-layer coating structure ensures superior adhesion, excellent

mechanical strength, and long-lasting anti-corrosion performance,

making it widely used in oil & gas pipelines, urban gas

distribution, and water transmission lines.

Technical Process Flow:

- Pipe Loading

- Screw Conveyor Transfer

- Surface Cleaning & Induction Heating

- Epoxy Powder Coating

- Adhesive and Polyethylene Extrusion Coating

- Cooling Spray Treatment

- Pipe Unloading & Grinding

Key Specifications:

- Pipe Diameter Range: 159mm - 1400mm

- Extrusion Output: ≤350 kg/h

- Application: Steel pipe external anti-corrosion coating for buried

pipeline systems

Applications:

Application

The three-layer PE process, with the epoxy powder coating as bottom

layer, binding and bundling through polyethylene PE and adhesive,

is widely used in anticorrosion of steel pipes, and applied to the

oil, natural gas, chemical material, water pipelines.

Question & Answer:

Q1. What is Size of Pipe Dia. your equipment can produce ?

A: We can produce four main Model: Diameter of steel Pipe:48-219mm,

219-1220mm, 800-1600mm, 1000-2400mm

Q2. What is Descaling grade?

A: SA2.5

Q3. What is your anticorrosion coating standard?

A: It can meet SY/T0413-2002 ,GB/T23257-2009, German DIN 30670 ,

DIN 30678 and coating specification requirements from American

Corrosion Association, and DNV . The product pipe fully complies

with SY/T0315-2005 ,CNPC38-2002 "Technical specifications for

double-layer fusion-bonded epoxy powder coating on buried steel

pipe and Canada, American Corrosion Association standards

Q4. What is Delivery Time

A: 2-3monthes after deposit

Q5. Production output

A: It is different output capability as different pipe diameter,

the Max. is 3 to 8 km/day,and annual processing capacity is 2

million square meters (Φ508 mm)

Q6. Coating thickness:

A: 80~800um

Q7. Which country did you sell your 3PE equipment?

A: We have produced nearly 50sets 3PE processing line at home and

abroad. Such as Russia, Iran, UAE, Iran, India, Belarus, Kazakhstan

and so on.

Q8. After-sales service:

A: Warranty period: Before delivery all the equipment must be trial

operated to confirm the quantity perfectly.The warranty period is

12 months from the date of pick-up for mechanical part , and 6

months for the electrical part.

Service:The seller provides technical services and provides

training and guidance to buyer operators.

Customization:

Product Customization Services for the 3LPE Coating Pipe Production

Line:

Brand Name: Huashida

Model Number: 50-4200mm

Place Of Origin: Qingdao

Certification: ISO/CE/RoHS

Minimum Order Quantity: 1 Set

Price: $US100000-3000000

Packaging Details: Standard Package For Export

Delivery Time: 60 Days

Payment Terms: TT/LC/DP

Supply Ability: 30 Set/year

Substrate: Steel

Extruder: Single Screw Extruder

Coating Structure: Fbe, 2lpe, 3lpe

Coating: Powder Coating, Extrusion Coating

Model No: 50mm-4200mm

Keywords: Drip Irrigation Pipe Production Line, Ceramic Enamel

Coated Steel Pipe, 3PE/3LPE/FBE Coated Steel Pipe

Support and Services:

The Product Technical Support and Services for the 3LPE Coating

Pipe Production Line include:

- Installation guidance and support

- Operator training

- Troubleshooting assistance

- Maintenance advice

- Spare parts supply

- Performance optimization services

- Product customization options