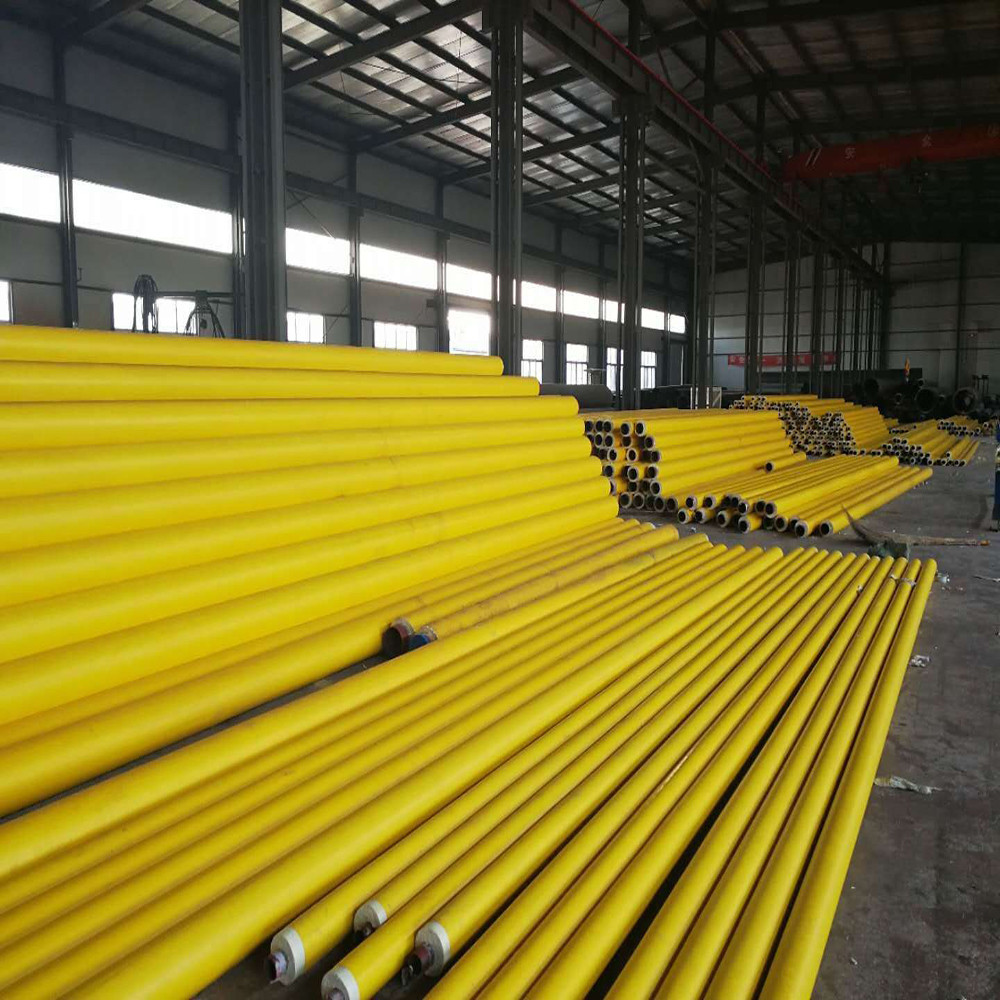

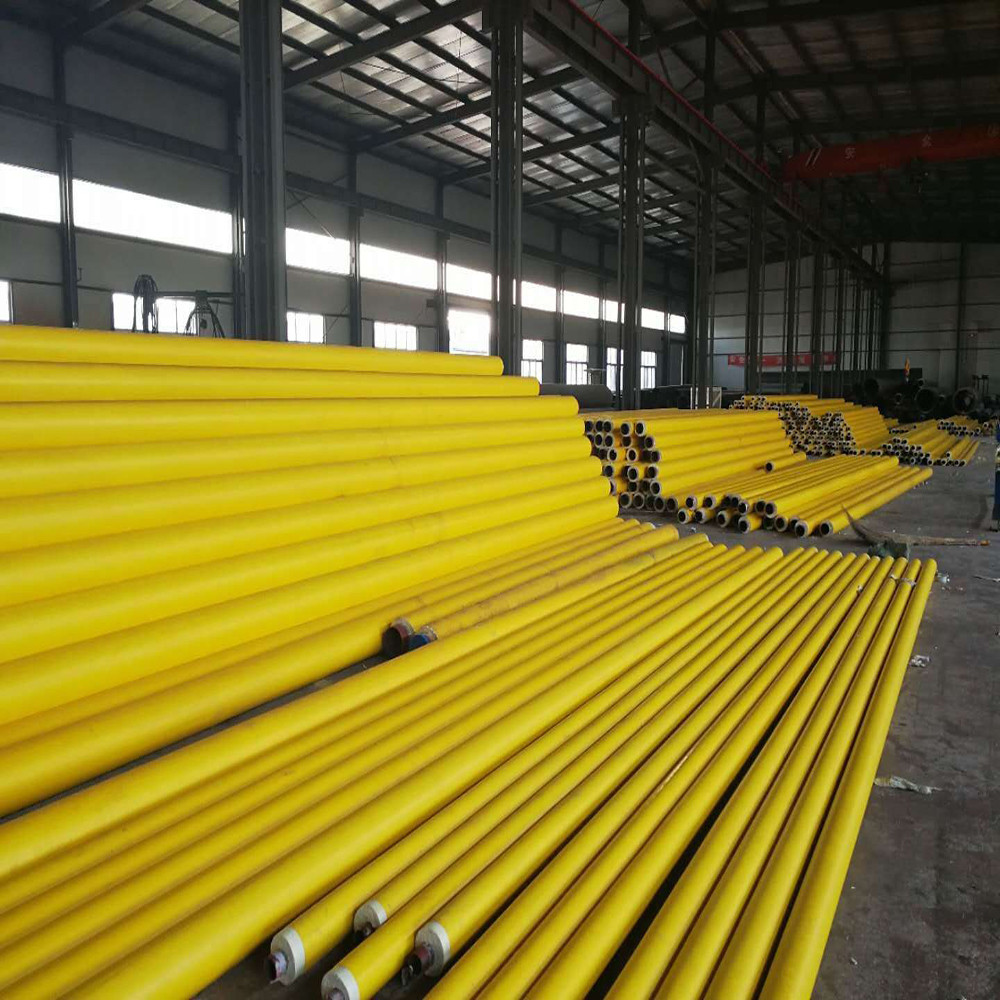

One-step Polyurethane Insulated Pipe Production Line

Product Overview

The "One-step" Foam Jacket Anti-corrosion & Thermal Insulation

Production Line integrates multiple processes, such as applying

anti-corrosion coatings, filling thermal insulation materials, and

extruding outer protective layers, into a continuous production

workflow. This streamlined approach enhances efficiency, reduces

costs, and ensures high-quality product output.

This equipment is primarily used for manufacturing polyurethane

insulated pipes. It ensures the tight bonding of the steel pipe,

insulation layer, and outer protective jacket, resulting in

durable, high-performance pipes. With its advanced automation, the

system minimizes manual operations, improving product stability and

reliability.

Pipes produced with this line are widely used in heating systems,

long-distance oil transportation, and buried thermal pipelines,

offering extensive application potential and excellent investment

returns.

Technical Features

- Versatile Material Options:

Corrosion resistance: Compatible with fusion-bond epoxy powder and

various coatings.

Thermal insulation: Options include high-temperature polyurethane

foam or black pitch foam.

Outer jacket: Black, UV-resistant, and anti-aging, ensuring

durability.

- Robust Layer Integration:

The jacket, foam, and anti-corrosion layers adhere firmly,

providing superior protection.

- Damage-free Rotation System:

Rubber wheels prevent damage to the anti-corrosion layer during

operation.

- Advanced Alignment Technology:

The Automatic Hydraulic Deviation-correcting Machine ensures stable

performance and precise rectification.

Technical Parameters

Steel Pipe Diameter Range: 32mm - 426mm

Processing Capacity: ≤250㎡/h

Surface Cleaning Grade: Sa2.5

Materials Used:

Black Material: Isocyanate

White Material: Polyether Polyol Mixture

Main Equipment

Steel pipe derusting equipment

PE extrusion machine

Forming molds

Deviation-correcting devices

Cooling equipment

Cutting tools

Pipe transfer systems

Spray marking system

Application Perspective

This "One-step" production line features a high degree of

automation and operates efficiently for pipe diameters ranging from

32mm to 426mm. The insulation coating produced complies with

national standards and is widely utilized in:

Long-distance oil pipelines

Directly buried heating pipelines

Cooling systems

By delivering continuous operation, high production efficiency,

energy savings, and environmental benefits, this line represents a

cutting-edge solution for thermal insulation pipe production.