Qingdao Huashida Machinery Co., Ltd.

1. Our Factory

Qingdao Huashida Machinery Co., Ltd. is located in Qingdao High &

New Technology Industrial Area- Qingdao Huashida industrial Park,

covers an area of about 4000 square meters. We have tens of years

experience in plastic pipe, sheet, and board extrusion lines, and

pipe joints and welding tools such as heat shrinkable sleeve,

Electro fusion sleeve etc.

2. Our main products

Our main products include as following,

HDPE PU pre-insulation Jacket Pipe extrusion line

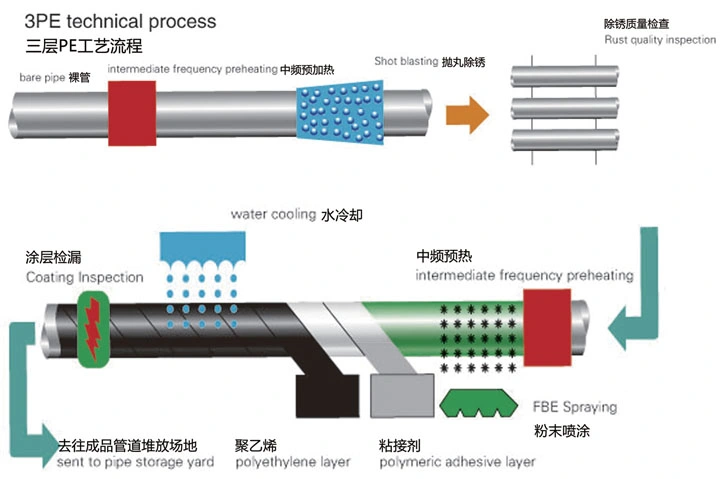

3PE steel pipe anticorrosion&coating machinery

Rubber&plastic foam flexible insulation tube/sheet production

line

HDPE water supplying pipe extrusion line

PE PP sheet board extrusion line

Heat shrinkable sleeve production line

Hollow wall spiral pipe production line

Plastic welding rod extrusion line

Radiation cross-linked PE heat shrinkable sleeve

Electro fusion tape

Portable extrusion welder

3. Our products Application.

Our machines make products what are widely used as jacket pipe of

PU foam insulation pipe in municipal heating pipe system; Municipal

water supplying and drainage pipeline; Oil and gas pipeline; Pipe

joints of plastic drainage water pipes, PU foam insulation

pipelines, 2PE/3PE oil and gas pipelines;

Besides manufacturing machines, we also make Heat shrinkable

sleeves and electro fusion sleeves and plastic welders, which are

widely used as pipe joints and sealings of plastic drainage water

pipes, PU foam insulation pipelines, 2PE/3PE oil and gas pipelines;

4. Our certificates and Patents

5. Our Purpose and Market

Our purpose is to supply highest cost-effective products and the

most suitable solutions to our clients, as well as intimate help

and service, on this basis we reach a win-win situation.

For over 14years We have exported to many foreign countries, such

as Russia, Iran, Turkey, U. A. E, Sudan, Ukraine, Uzbekistan,

Azerbaijan, South Asia, Poland etc.

6. Guarantee and after service

The guarantee period is 12 months from the date of installing, but

no more than 14 months from the date of delivery. After this period

we are obliged to provide with lifelong service at the expense of

Buyer.

During the warranty period we are responsible to provide trouble

shootings and help the customer to solve the problems, provide

spare parts which are broken, except breakings caused by the Buyer.

We will provide the technical service train the workers from the

buyers for free.

We can also send technicians to the buyer's companies abroad for

help installation and testing the lines. But the buyer shall pay

for the round trip tickets, accommodation, transportation, medicine

treatment and insurance of the technicians in foreign countries and

some salary accordingly.